IST636 high-energy MIXER MIll

IST636 mill have an option for unlimited milling time and 36 Hz oscillation rate, making it one of the highest-energy mixer mill available at the market.

IST 636 is our top-notch high-energy mixer mill with currently unprecedented frequency of oscillation of 36 Hz, making it an ideal choice for pulverization of extra hard materials or performing the mechanochemical synthesis where the high kinetic energy input is needed. This mill can also be successfully used for disruption of biological cells, same as IST500. As all advanced IST mills, it can be operated remotely, via a computer software or server.

The maximum milling time over remote control is 5 hours, but further flexibility can also be provided.

GENERAL INFORMATION FOR THE IST636 MIXER MILL

- Ball mill for grinding dry, wet, hard, soft and soaked samples or materials

- Input particle size – up to 10 mm

- Particle size after grinding – < 100 nm - 3 um (depending on the material)

- Number of grinding stations – 2 (up to 4)

- Volume of grinding jars – 1-250 mL

- Grinding jars and balls materials – stainless steel, tungsten carbide, zirconium oxide, aluminum, brass,

PMMA, PTFE, polyamide

- Adjustable vibration frequency – 3 to 36 Hz

- Adjustable grinding times – 30 s to 99 min (+ mode for unlimited grinding)*

- Option for computer control for longer grinding

- Mode for unlimited grinding time

- Power connection – 220-240 V / 50-60 Hz

- Power consumption – ca. 130 W

- Weight – ca. 23.5 kg

* it is not recommended to use the mill in an unlimited grinding mode overnight without supervision

ADDITIONAL ADVANTAGES

- High-energy milling for demanding samples

- Configured for in situ monitoring by synchrotron X-ray diffraction and Raman spectroscopy

- Air cooled to prevent overheating of reaction vessels and the mill

- Overnight or long-term grinding

- Lowered noise level: below 67 dB during grinding

- Option of additional custom equipment:

- Adapter for 2 additional milling vessels

- Software for remote control

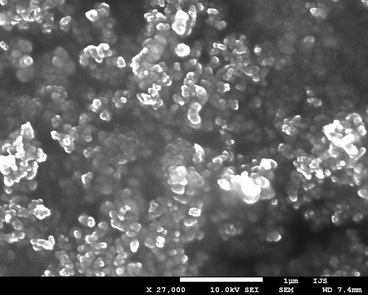

Scanning tunneling microscope (STM) imaging of

a coordination metal-organic sample milled for 60 minutes at 30 Hz using one stainless steel ball weighing 4 g.