EQUIPMENT FOR IN SITU MONITORING

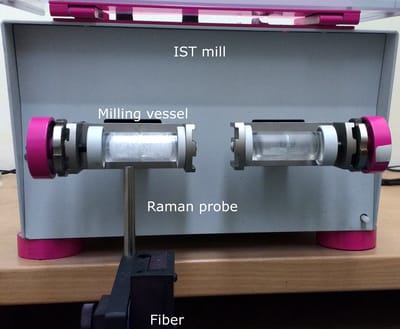

Experimental setup for laboratory in situ Raman monitoring

Experimental setup for laboratory in situ Raman monitoring

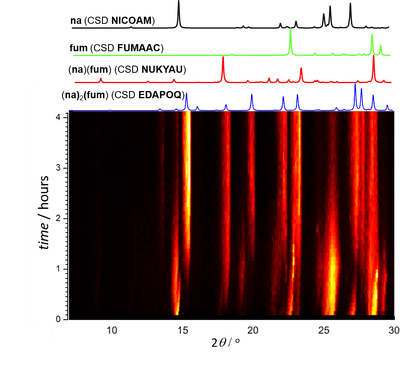

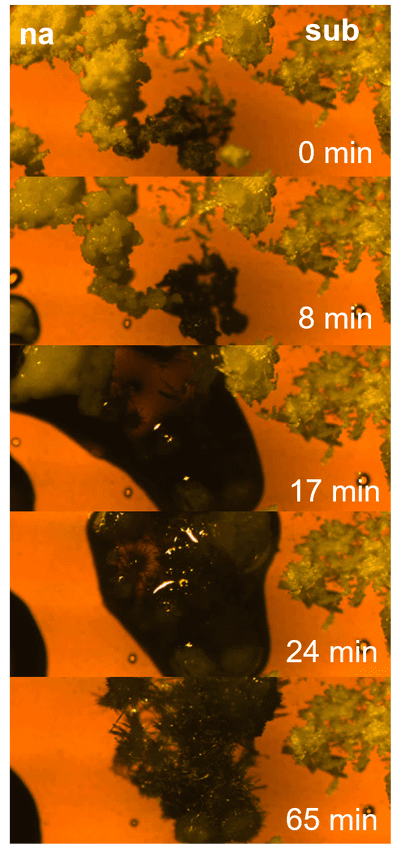

Recently developed in situ monitoring techniques based on synchrotron X-ray diffraction[1] and Raman spectroscopy[2] changed the whole mechanochemical community and enabled unprecedented knowledge on the milling reactivity. The two methods could even be used simultaneously and quantitatively to gain even deeper knowledge on the mechanisms of milling process.[3]

These methods showed the complexity of mechanochemical milling reactions, revealing intermediate phases never observed in other synthetic procedures and offered a direct insight into the kinetics and mechanisms of milling reactions without the need to stop the mill for sampling. Observed intermediates could even be isolated and characterized or used for further synthetic requirements.

We offer equipment needed for performing the in situ monitoring, from vessels to mills, which are all adapted for this kind of measurements.

RAMAN MONITORING SYSTEM

We also offer complete system for in situ Raman monitoring. Contact us!

THERMOJAR[4]

Complete system for high-precision (±0.03 °C) in situ and direct monitoring of mechanochemical milling reactions in mixer mills.

ADAPTATION OF YOUR EQUIPMENT

If you already have a mill which you would like to adapt for in situ monitoring, contact us! We will try to find the best solution for your problem.

These methods showed the complexity of mechanochemical milling reactions, revealing intermediate phases never observed in other synthetic procedures and offered a direct insight into the kinetics and mechanisms of milling reactions without the need to stop the mill for sampling. Observed intermediates could even be isolated and characterized or used for further synthetic requirements.

We offer equipment needed for performing the in situ monitoring, from vessels to mills, which are all adapted for this kind of measurements.

RAMAN MONITORING SYSTEM

We also offer complete system for in situ Raman monitoring. Contact us!

THERMOJAR[4]

Complete system for high-precision (±0.03 °C) in situ and direct monitoring of mechanochemical milling reactions in mixer mills.

ADAPTATION OF YOUR EQUIPMENT

If you already have a mill which you would like to adapt for in situ monitoring, contact us! We will try to find the best solution for your problem.

REFERENCES

[1] T. Friščić, I. Halasz, P. J. Beldon, A. M. Belenguer, F. Adams, S. A. J. Kimber, V. Honkimäki, R. E. Dinnebier, Real-time and in situ monitoring of mechanochemical milling reactions, Nature Chem., 2013, 5, 66.

[2] D. Gracin, V. Štrukil, T. Friščić, I. Halasz, K. Užarević, Laboratory real-time and in situ monitoring of mechanochemical milling reactions using Raman spectroscopy, Angew. Chem. Int. Ed., 2014, 53, 6193.

[3] Stipe Lukin, Tomislav Stolar, Martina Tireli, Maria Blanco, Darko Babić, Tomislav Friščić, Krunoslav Užarević, Ivan Halasz, Tandem in situ monitoring for quantitative assessment of mechanochemical reactions involving structurally unknown phases, Chem. Eur. J. (2017), 23, 13941–13949.

[4] K. Užarević, N. Fedelji, T. Mrla, P. Julien, B. Halasz, T. Friščić, I. Halasz, Enthalpy vs. Friction: Heat flow modelling of unexpected temperature profiles in mechanochemistry of metal-organic frameworks, Chemical Science, 2018, 10.1039/C7SC05312F